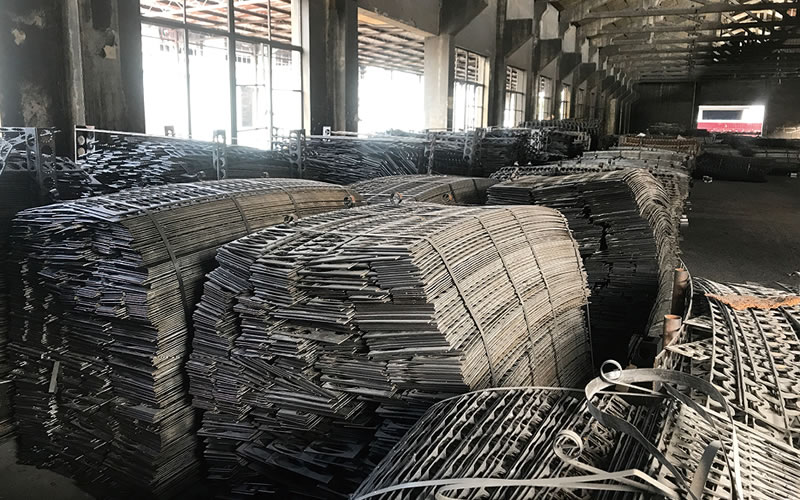

● We are very pay attention to the choice of the scrap steel。Clean,high quality of materials。

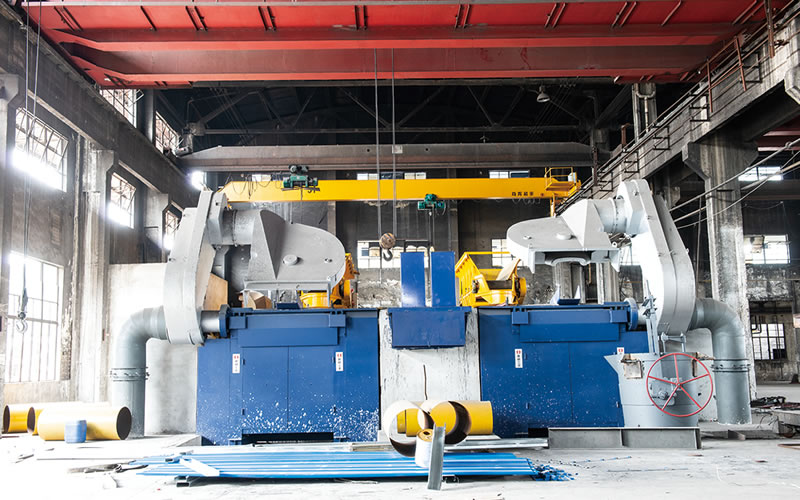

● Smelting medium frequency coreless induction furnace, acid lining, no oxidation smelting process, silico-manganese precipitation deoxidation, deoxidation aluminum.

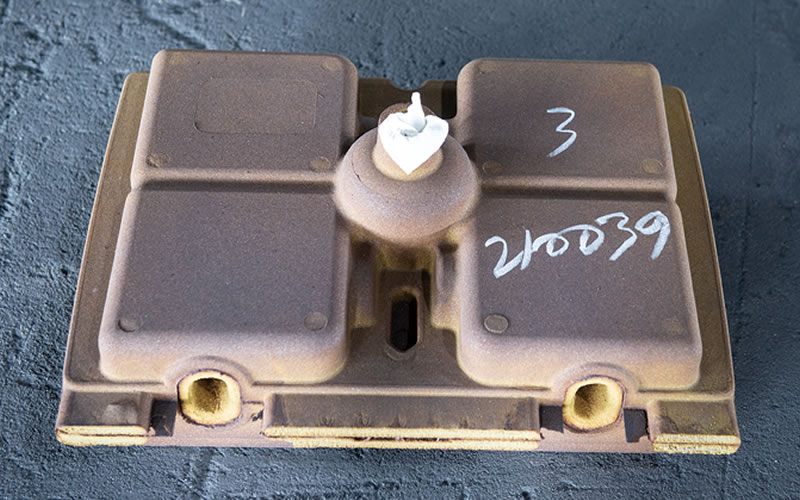

● The model adopts the method of the resin coated sand, hot core box system type, core-shell combined manner.

● Pouring breaking the original mode, using more advanced stage antes way, combining calm technology, with the advantages of convenient temperature control, oxidation of mixed with less, pouring can realize steel, slag separation, safe and reliable operation, the advantages of less labor.

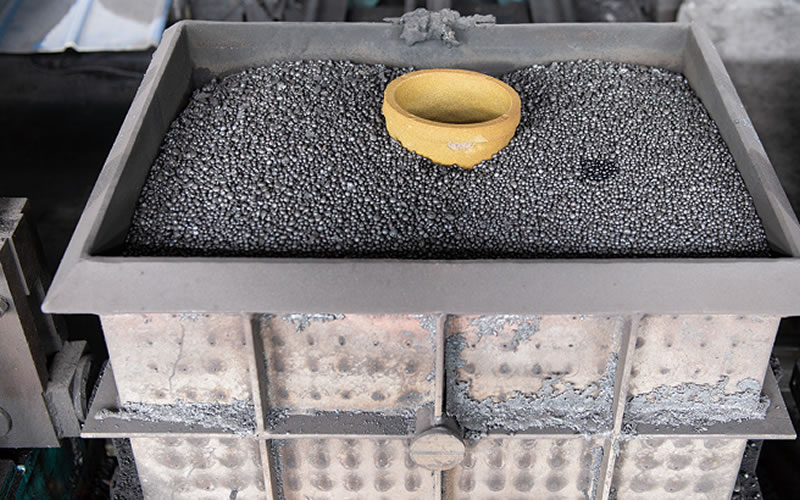

● Special introduction, with two automatic shell type transmission line, automatic iron pill box, equipped with the bottom note, because of the proportion of iron pills and the effect of the stimulation, the production of angular parts with size stability, structure compact, no inclusion (slag) and other defects, mechanical performance is higher, so that with more safe and reliable advantages.

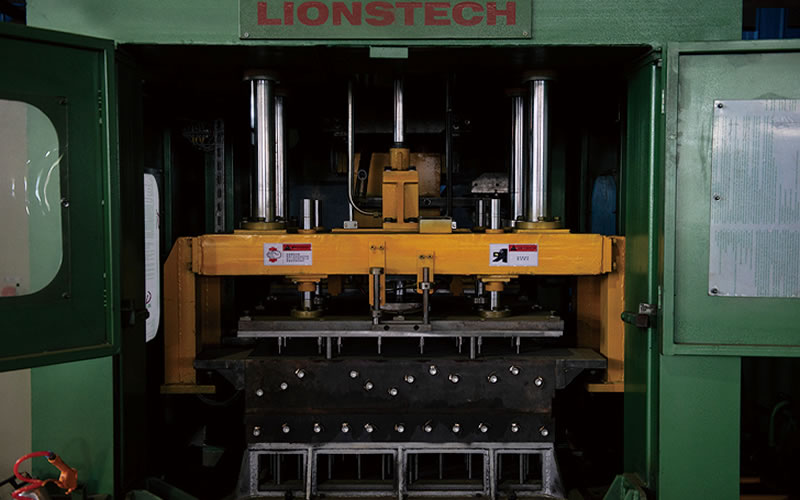

● The machine is equipped with a combination of double side milling machine with hydraulic fixture, with accurate positioning, clamping reliable, and the maximum use of equipment to reduce the human factor.

● Heat treatment using specially designed for the continuous production of automatic temperature control Gas stepping pusher furnace, the experimental verification, this device using PID control system with high precision temperature control, and due to pipeline gas pressure is relatively stable, thermal fluctuations small, uniform heating, heat sealing properties, and high cooling rate, coupled with the feedback nozzle combustion system, better combustion, higher utilization and more energy efficient. Casting heat treatment quality is further ensured.

● Cleaning up after the road using hook type shot blasting line and crawler machine used, with good cleaning effect, reducing product bump each other, which makes products with better aesthetics.

● Protective treatment with zinc rich paint dipping coating method, equipped with a stirring device hanging chain ring leaching paint line was used, compared with manual spraying, has the advantages of uniform coating, high efficiency, and small environmental pollution

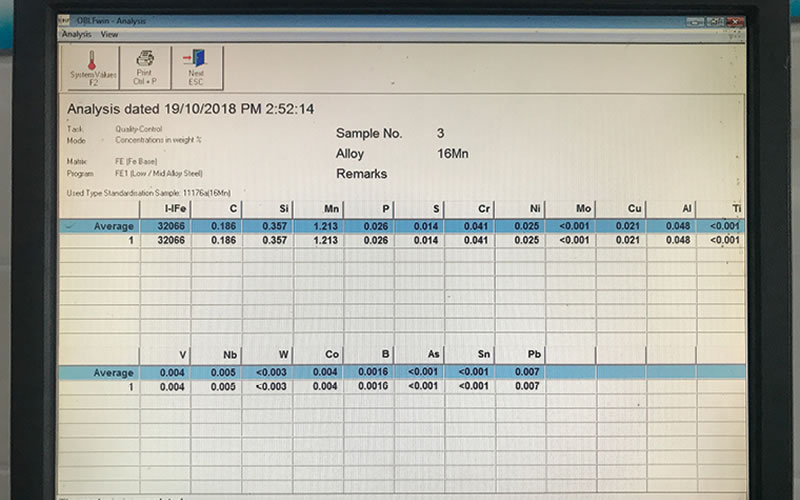

● Corner castings tests include tests of chemical elements (C, Si, Mn, P, S five elements and a series of micro-alloying elements) and mechanical tests (tensile test: yield strength, pull-off strength, elongation, reduction of area; hypothermia impact test: -20 ℃ impact energy).

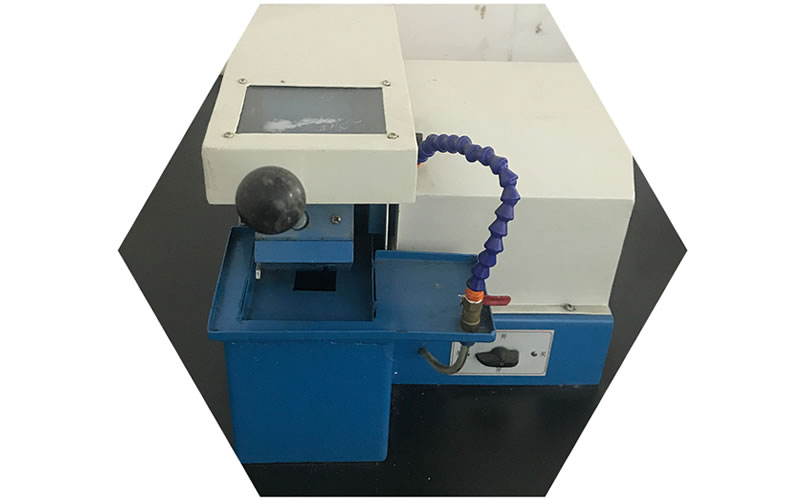

● Laboratory is equipped with Germany OBLF GS1000 direct reading spectrometer, spectral sampling machine, stove, furnace, product sampling and analysis; testing speed is fast, accurate, real-time detection, real-time control, which ensures the accuracy of each furnace chemical composition.

● Tensile test, with ETM3050 WANGE type microcomputer control electronic universal testing machine, fully automatic computer printing and output to ensure the validity of the test, authenticity, accuracy.

● Low temperature impact test, the domestic "Tongli" JBD-300B automatic temperature impact test machine, the operation is convenient, safe and reliable. With temperature control automation, sample automation, reducing the impact of human trials.

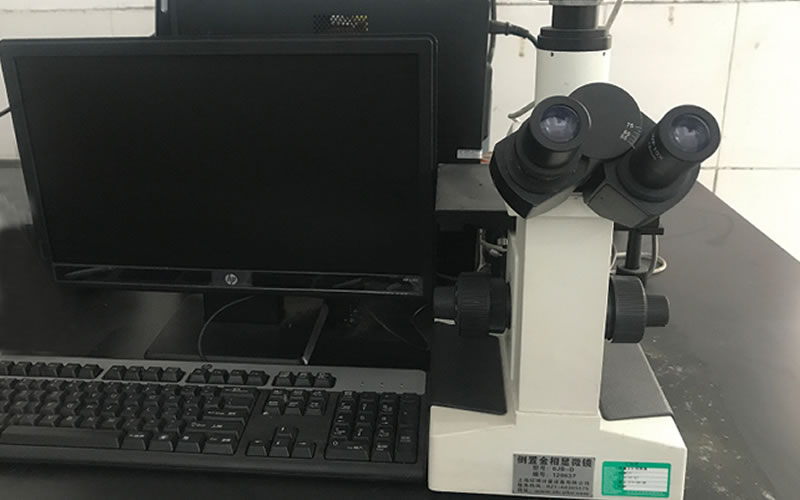

● The fracture surfaces were examined by means of visual or low, and the appearance of the fracture and the abnormal structure of the fracture were complemented by the high - and - time metallographic examination

● 另外配备有相关的试样加工设备,(铣床,磨床,刨床,线切割,锯床),冲击试样缺口拉床,冲击试验缺口投影仪,布氏硬度计,金相试验制样机,切割机,三目倒置式金相分析仪,超声测厚仪等一系列辅助试验设备。

● Also equipped with relevant sample processing equipment (milling machines, grinders, planer, line cutting, sawing), impact notch broaching machine, impact test gap projector, Brinell hardness, metallographic test system prototype, cutting machine, trinocular inverted metallurgical analyzer, ultrasonic thickness gauge and a series of auxiliary test equipment.

● These tests in sampling and sample preparation, processing, and test are required to distinguish in the course using photogravure and sign of the angle itself, strictly identify and transfer, if necessary, fill stamped methods can be used to screen to ensure representativeness of the test corner castings.

● Visual inspection & 100% full inspection. Specific methods and discrimination based on "products quality inspection method and disposal".

● The dimension inspection and weighing of corner castings, according to the sampling inspection method. Size control focused "three inspection" system operator dedicated gages self-test, quality control staff gage inspection, inspection personnel measuring the seizure.

● All of the above involves measuring tools, gages, equipment, instruments and meters are required to be calibrated on a regular basis to identify and formulate relevant rules should be consistent with national standards and the requirements of the competent authority.